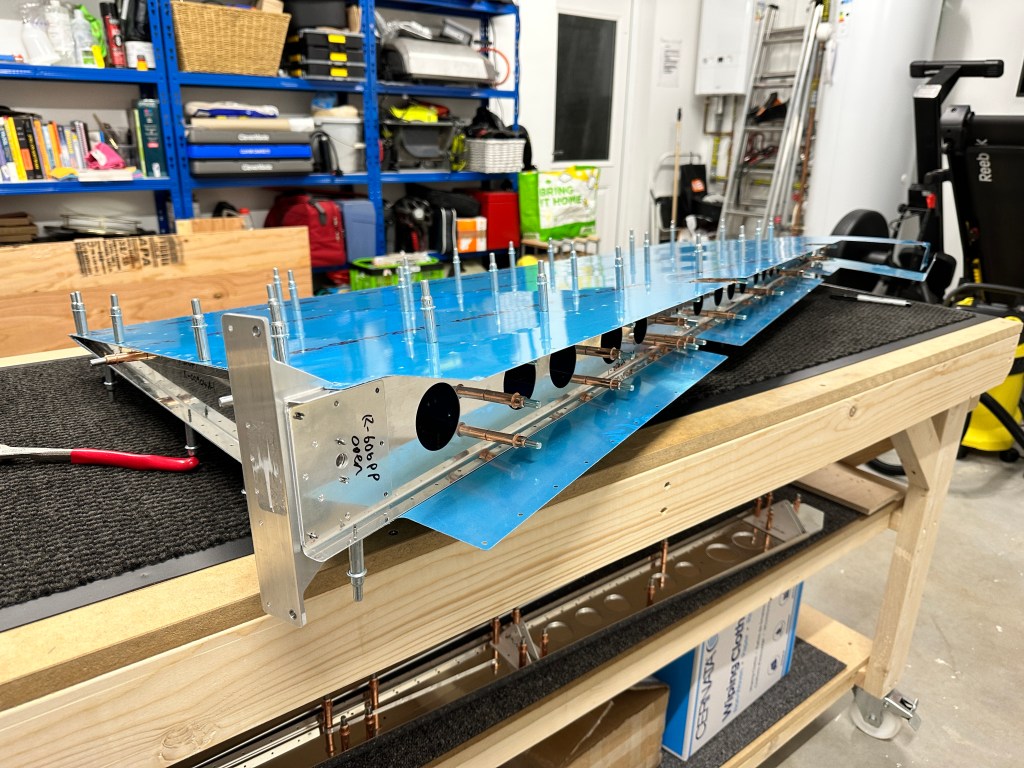

Started priming the rudder parts today. I have decided to use Upol Acid #8 in rattle cans for priming. I have a previous post where I compared a few, and this was by far the one I liked the most.

Nothing fancier than this old wine rack that my wife was about to throw out when I gave it this new lease on life! Protecting the slabs with cardboard in the garden, but I did buy a paint tent, so I will need to give that a try – but this kept things simple!

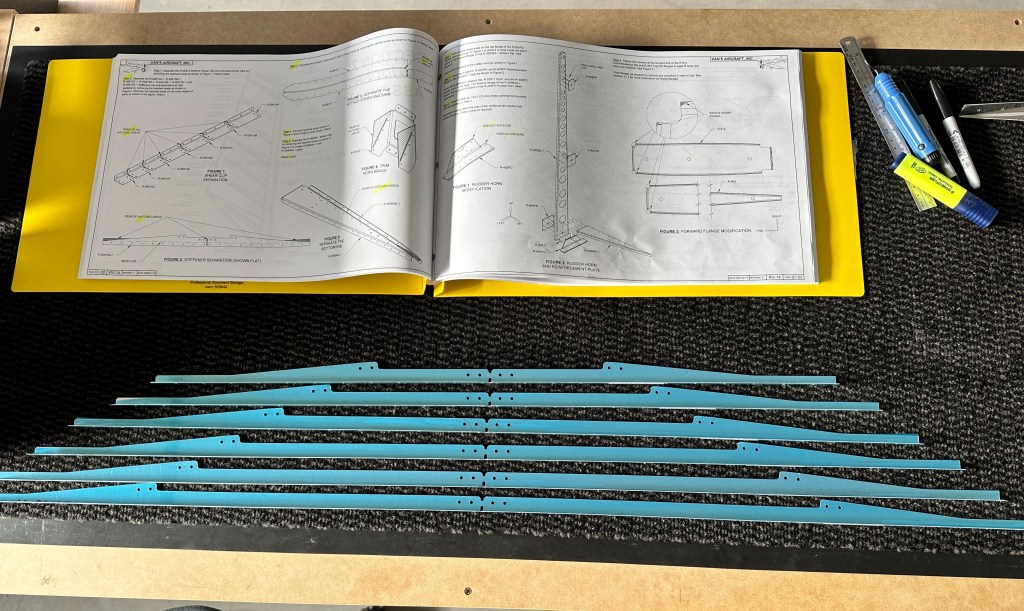

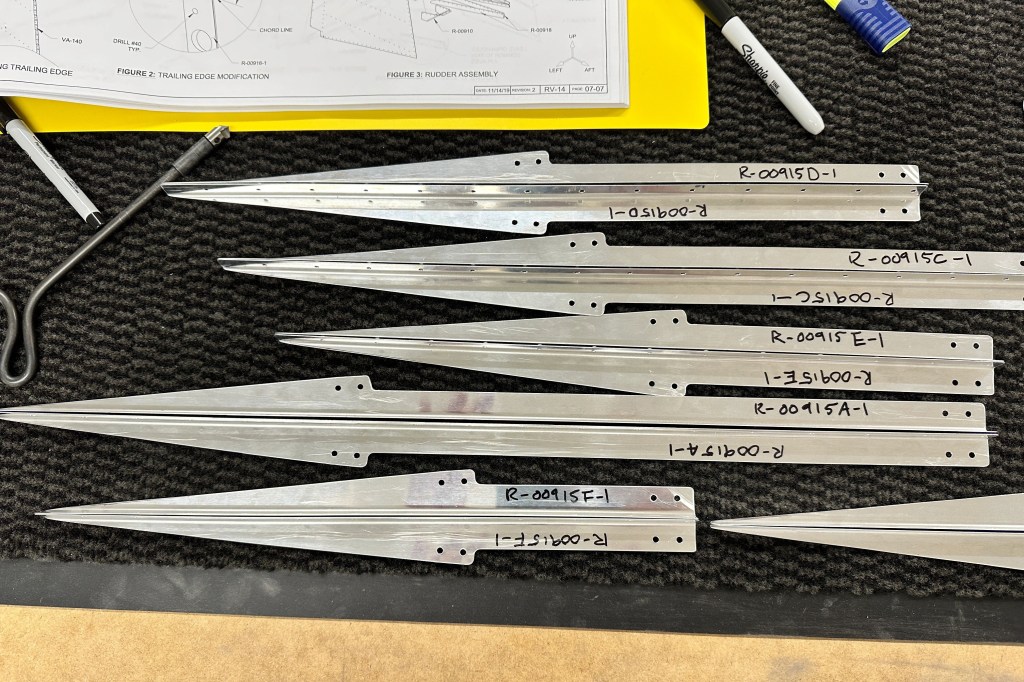

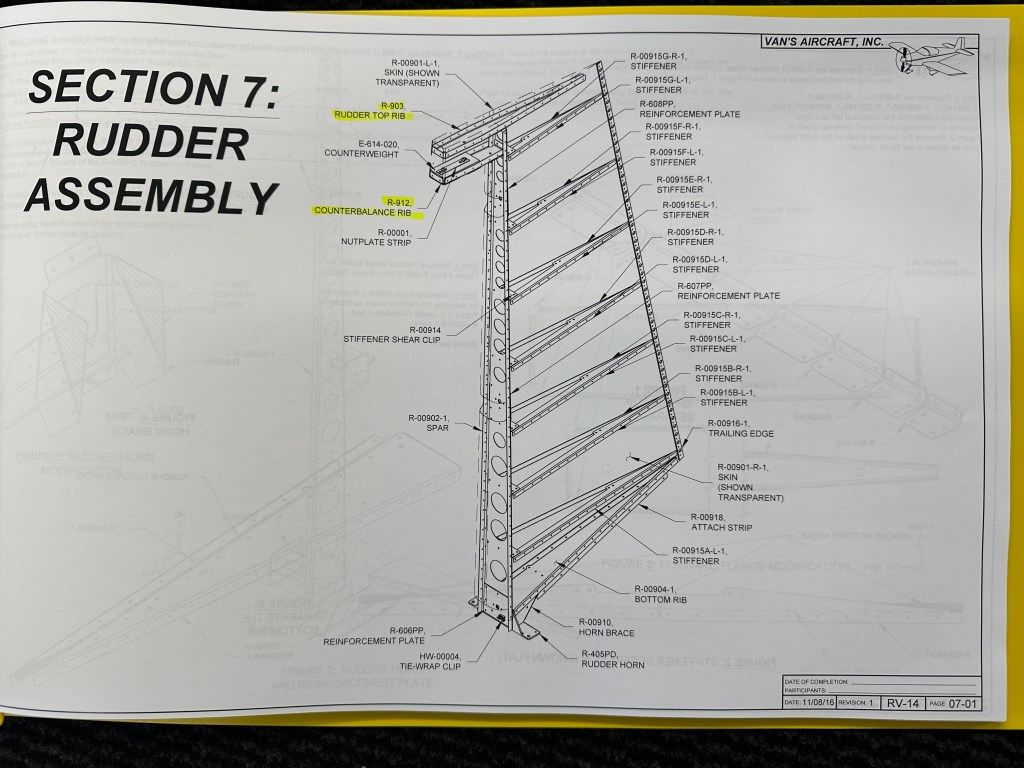

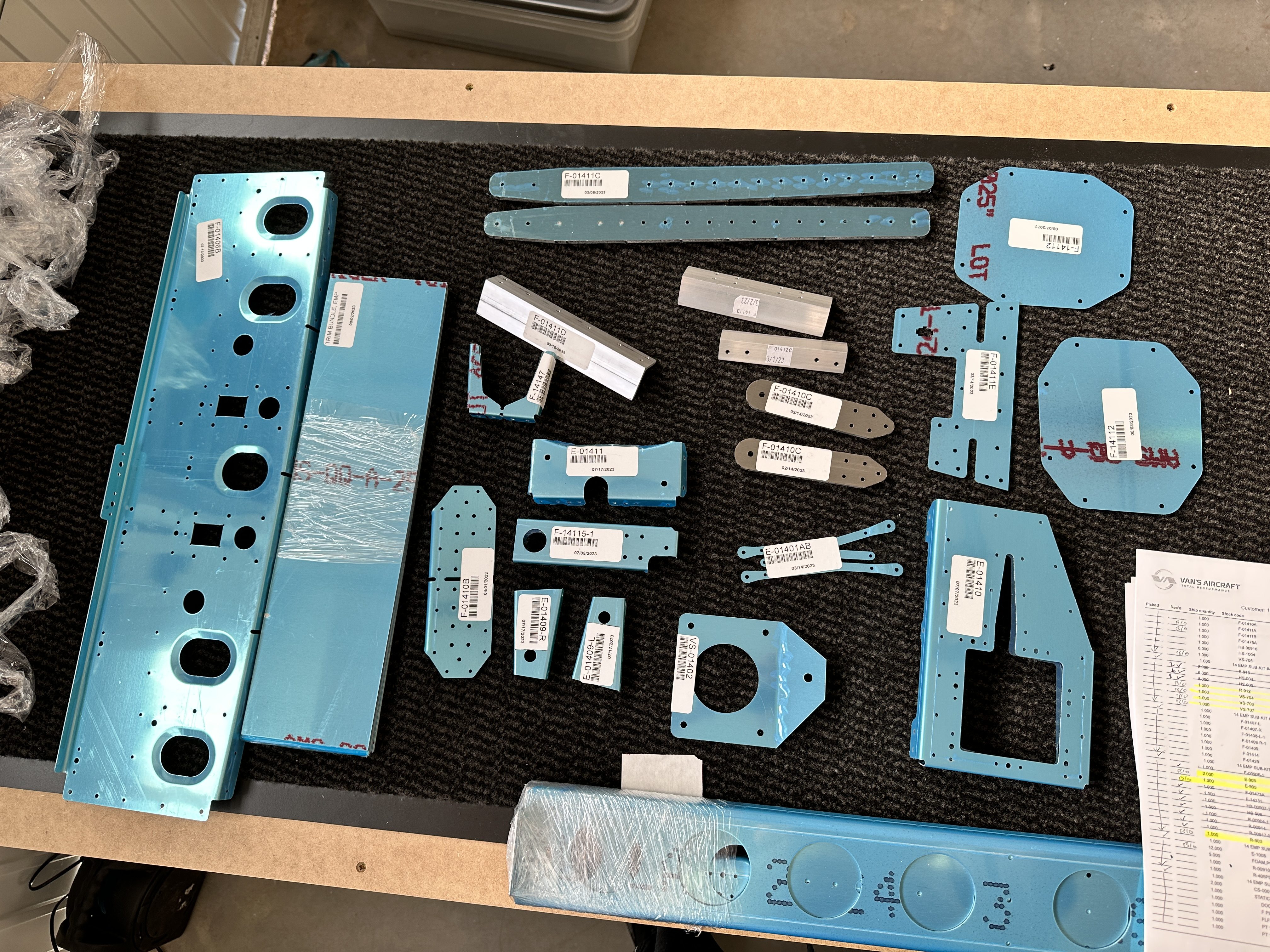

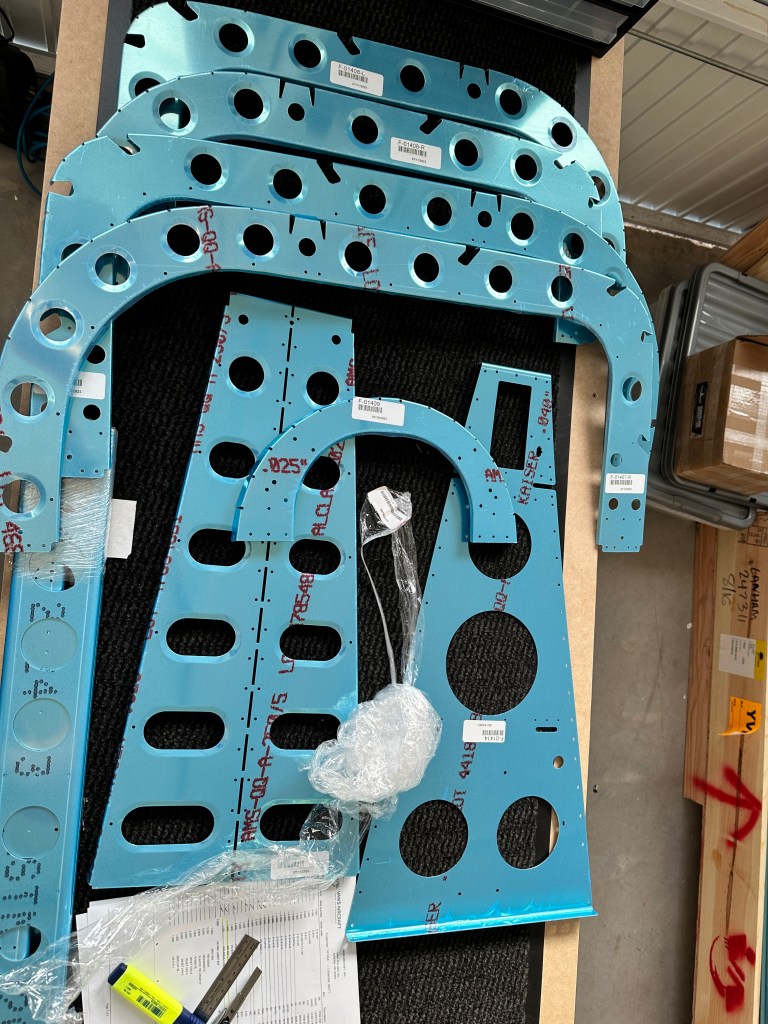

Before I started degreasing & priming, I took the time to take photos of the parts and ensure that I re-added the part numbers afterward – I didn’t want to end up with a load of parts I couldn’t identify!

When I was considering using the Stewart Systems primer, I purchased a kit and ended up with some leftover EkoClean. Therefore, I decided to utilize it to clean the parts using a Scotch-Brite pad. Afterward, I used water and dried everything with a combination of a microfiber cloth and non-linting wipes.

Then onto priming, is it weird that I really like the color of this primer? It’s obviously not going to matter as it’ll be internal – but still, nice grey color, may use this or similar for the cockpit!

Seem to have used most of the rattle can for these parts and that didn’t include the skins so that feels like a lot? Will keep an eye on things as I progress and maybe I’ll consider trying the spray gun again to see if it’s easier to use with Upol than it was with other variants.