So, as per my previous post I started out by comparing the process of alodining vs spraying, so here’s some ramblings about the results of that test, which has also resulted in trying a 3rd product.

Alodine

The results I achieved from this process actually look good. The parts came out with a golden color, maybe slightly darker in some areas – but I think that might be because I applied it with a brush instead of submerging the parts in a solution.

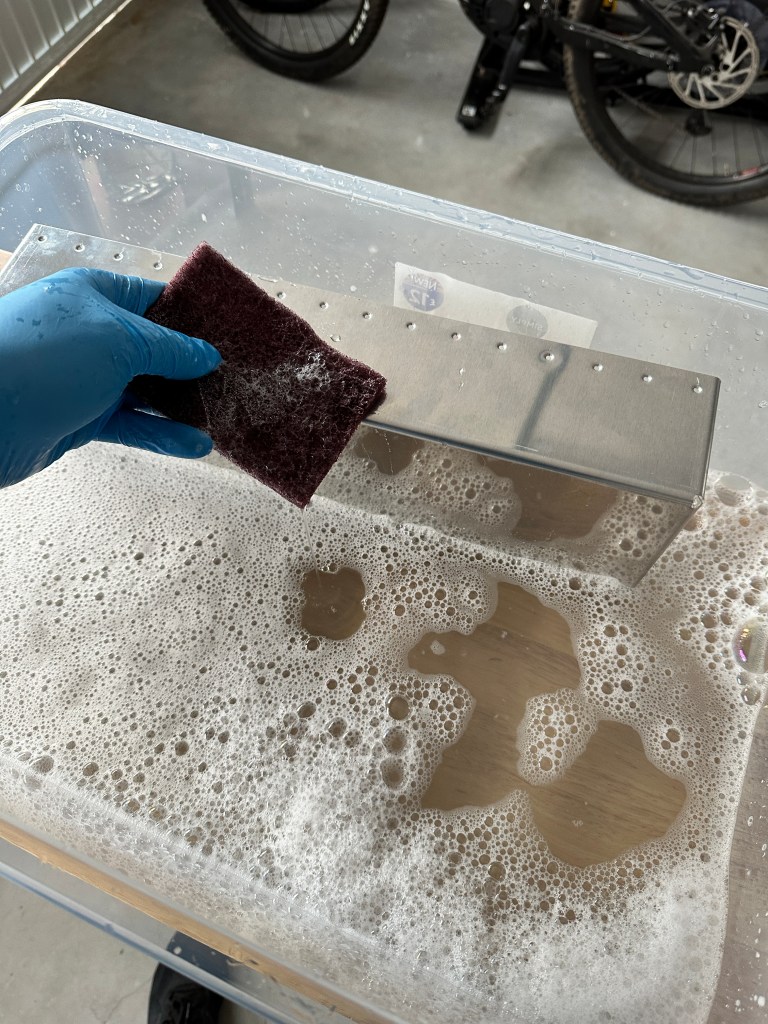

The first step after cleaning involved brushing on Deoxidine. I could really smell the vapor despite wearing a mask, and it was quite strong – so I ended up ventilating the area more and stepping outside for a while. It did a good job of cleaning the parts, so I proceeded to the next step.

Brushing on the Alodine (which I mixed from 2 parts) was really easy. I didn’t notice as much vapor smell as with the Deoxidine, and using a brush helped minimize waste. I left it on the parts for 2 minutes, constantly brushing more onto them to keep them wet – although I think it may have needed more time.

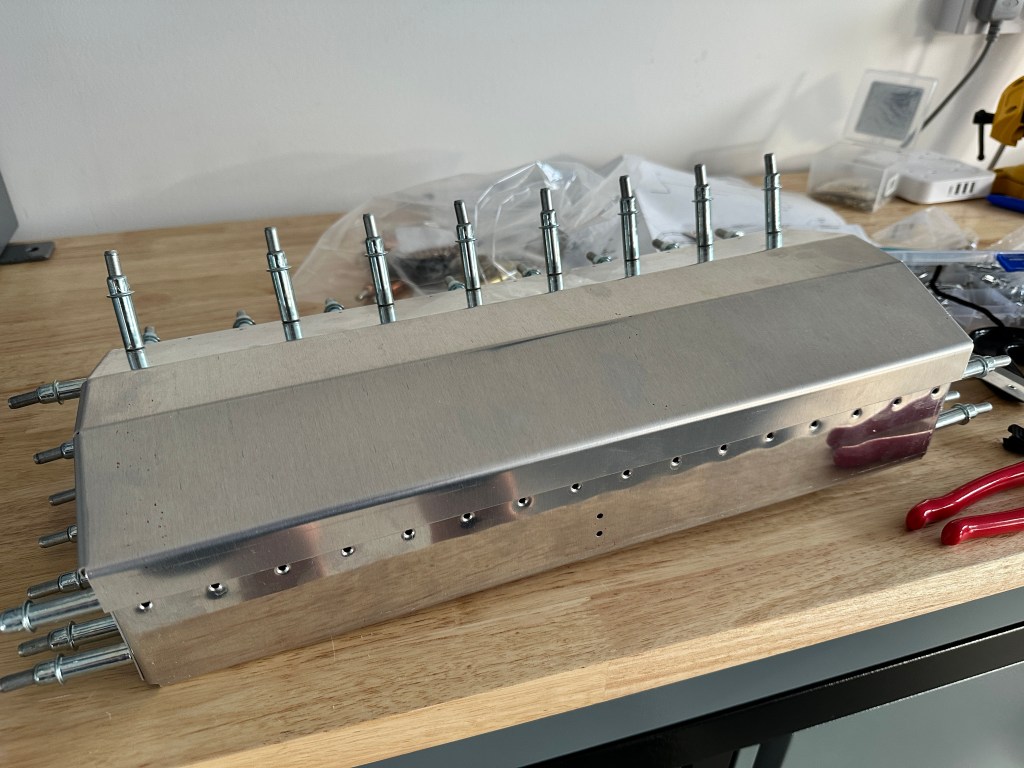

Compared to spraying, I definitely prefer this method. However, when considering the volume and size of the parts I would be working on in the kit, there are some practical challenges that I would need to overcome.

EkoPrime

This was basically a total failure, no doubt all because of me and my lack of experience, but here are a couple of things that I think contributed to it – and maybe I’ll try again.

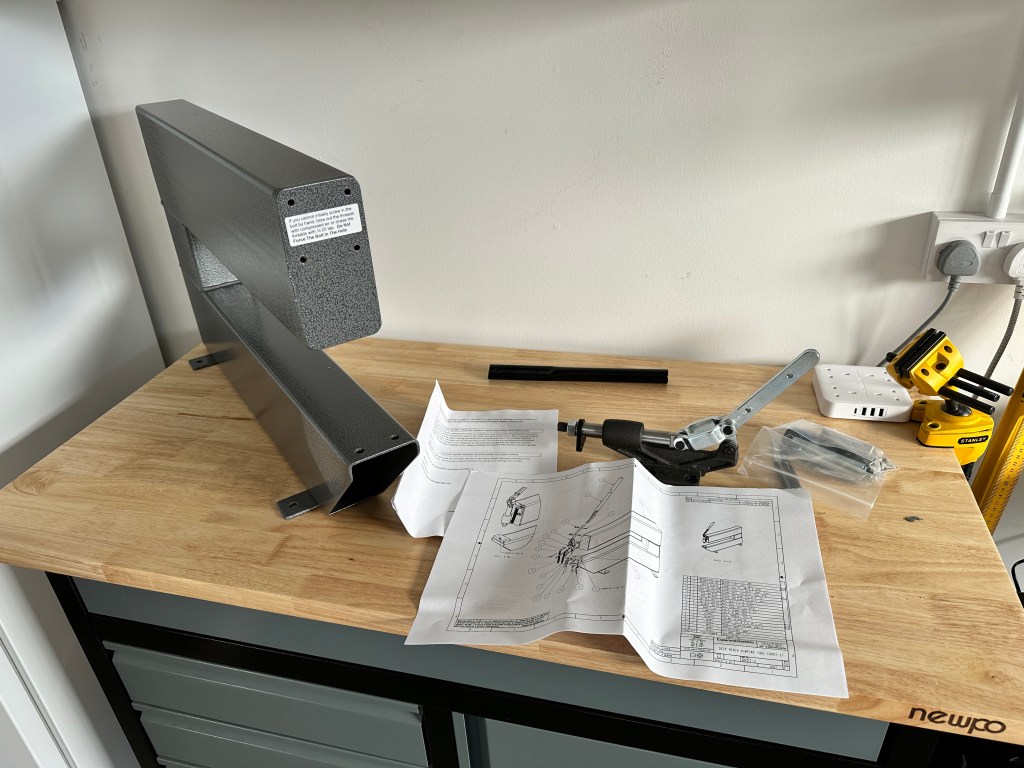

Firstly, I have no experience with a spray gun, I watched many videos on YouTube about how to set up the gun, spray patterns, etc, but still felt like a complete beginner. My compressor is small, and I used the inexpensive gun that came with it, so maybe that really affected the process – I’ve ordered another gun to see if it makes a difference (although I may return it if the other options are better).

Secondly, I wonder whether the alodined parts didn’t have the bite needed for the paint? I’d obviously went through an etch phase before the alodine process, but it didn’t seem like the paint was settling, it just seemed to sit on the surface liked spilled milk – I decided to wipe it off which was surprisingly easy…

Upol Acid 8 1K Etch Primer

I had originally planned to compare Alodine and spraying, but after spraying didn’t work at all and the Alodine process involved a lot of chemicals, I decided to try an etch primer in an aerosol can instead.

I had previously seen good results from people using Upol Acid 8 1K Etch Primer, which you can buy from Halfords. So, I went there and bought a can of it. You can also get it in a tin for spraying, but I didn’t want to go down that route because of my previous unsuccessful attempt.

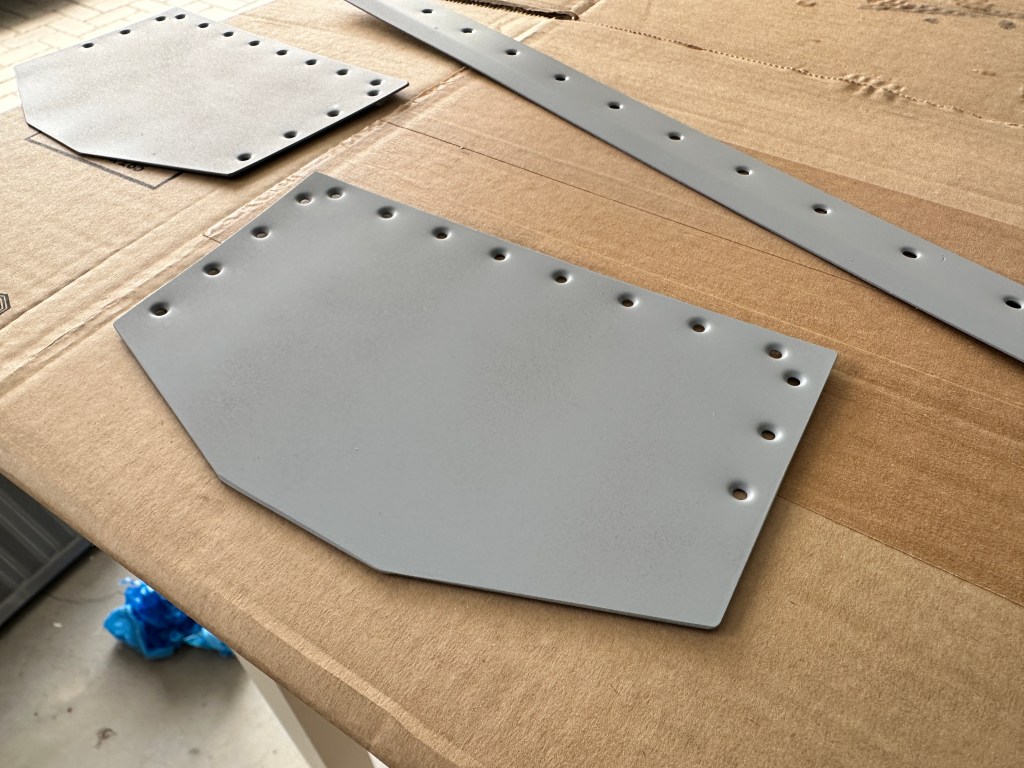

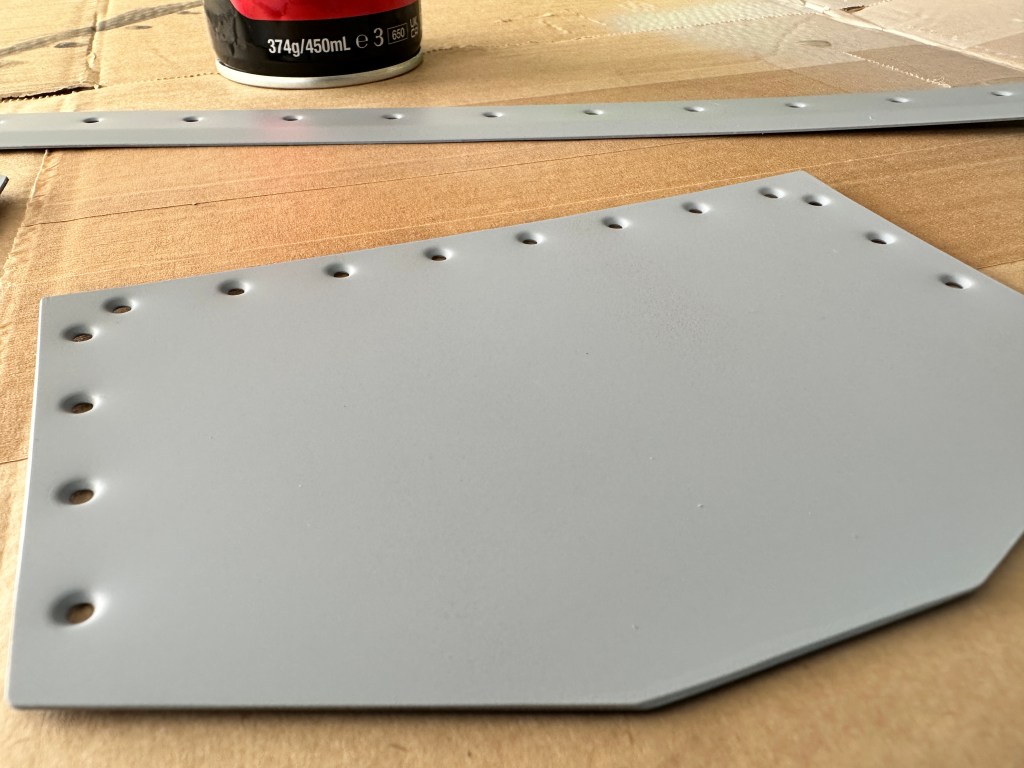

Using the aerosol can to spray the primer on the parts was really easy and enjoyable. It required very little clean-up, except for some overspray. The primer went on the parts smoothly and in a thin layer, and it was easy to use without needing a lot of equipment.

I’m almost certain that this is the method I will choose to use!